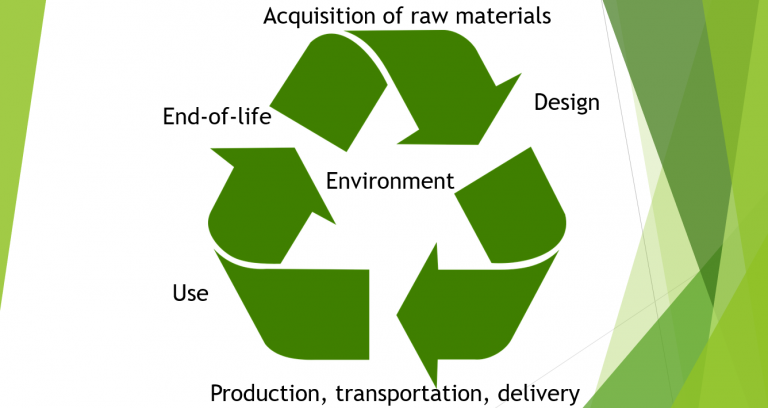

Article 3.3.3 of ISO 14001 defines a life cycle as consecutive and interlinked stages of a product system. Life cycles consist of product life cycle phases, from the raw material acquisition to the end of usability and disposal. This concept applies particularly well to manufactured products and Product Life Cycle Assessment (LCA). Here is an example of a product life cycle:

On the above Möbius strip recycling symbol, you can see the following five broad product life cycle phases:

1. Acquisition of raw materials to develop and manufacture a product;

2. Design stage, where a prototype will have its final shape, functionalities, and options;

3. Production or manufacturing. It ranges from small scale to mass production and includes the transportation and delivery of the products to the consumers;

4. Use by consumers, including product repair and reuse;

5. End-of-life which covers:

a. The final disposal of the product by the consumers;

b. Its collection by recycling facilities;

c. Recycling and materials recovery processes;

d. Refinement of waste co-products (as energy, etc.); and

e. The final waste into landfills.

The environment plays a central role in the product life cycle since it provides natural resources (water, air, minerals, wood, etc.) and energy to the five stages. The industry tends to economize, reuse and recycle natural resources and energy to improve efficiency and alleviate the weight on the environment.

In electronics, various environmental requirements control different stages of devices life cycles. Their goal is to lower the impact on the environment in all phases. Here are some examples:

Life Cycle Stages of Electronic Devices | Examples of Environmental Aspects | Examples of Standards or Regulations |

|---|---|---|

1. Acquisition of raw materials | Consumption of heavy metals, hazardous substances, minerals (tin, gold, etc.), and other natural resources | |

2. Design | Development of hardware (made of various materials) and energy-related products | |

3. Production, transportation, delivery | Consumption of energy (factory, trucks, etc.) and consumable materials (solder on assembly lines, packaging, etc.) | Regulations on emissions to the air, the soil, water, etc. ISO 14001 can help manage these requirements. |

4. Use | Consumption of energy to use the device | Product Energy Efficiency as defined during ecodesign. |

5. End-of-life, treatment, and final disposal | Consumption of energy (recycling facilities, transportation), production of hazardous waste, e-waste |

A manufacturer of electronic equipment developing a product life cycle approach may particularly pay attention to these requirements:

Ecodesign processes consist of considering environmental aspects when imagining and developing a new product prototype.

Some ecodesign regulations and other requirements apply to electrical and electronic products. For example, designers must strive to make their products with high repairability and recyclability. They should avoid hazardous chemicals and foster materials that other applications can easily reuse. Ideally, consumers can replace spare parts without changing the whole unit. They can also update software without upgrading the product, etc.

Ecodesign supports a circular economy approach, where the waste of an industry becomes the resource for another.

Eco-designers aim at making their products as energy-efficient as possible. As a result, users will enjoy low-consumption devices from standby to full power modes. Less energy consumption means fewer costs for the user and potentially fewer gas emissions per product when the energy comes from non-renewable energy.

Because of hazardous substances, waste of electrical and electronic equipment (WEEE) requires specific treatment. Recyclers must sort WEEE into separate waste channels that are distinct from other consumer waste like papers, plastics, or food residues.

Environmentally sound WEEE treatment can be complex and costly. Laws in various countries attempt to finance and organize the collection of WEEE. Notably, Europe and North America have implemented e-waste regulations in this regard. Nevertheless, most WEEE is still not recycled appropriately.

Life Cycle Assessments (LCAs) are systematic methods for analyzing product environmental impact. They are powerful tools for improving the processes by which something comes to market. A good life cycle assessment will begin by clearly defining the scope and purpose of the analysis. LCAs combine qualitative and quantitative factors to describe the impacts of a product, service, or process.

Once data collection begins, experts conducting an LCA usually follow three main steps: inventory, impact, and improvement analyses. Afterward, a well-designed LCA will allow us to classify and deconstruct the steps in a production plan.

LCAs fall under the ISO 14040 family of standards. ISO 14040 defines a life cycle assessment and how it gets constructed, while ISO 14044 describes more specific guidelines for performing the analysis. Together, they address the importance of rigor when collecting data and calculating results. Typically, your product information drives a specialized LCA software suite, which analysts use to create custom optimization strategies.

We can assist you with product life cycles and life cycle assessments at any stage. Ask Enviropass for a free consultation!