Persistent Organic Pollutants (POP) regulations apply to most products sold in various countries worldwide. Here are the current EU POP substances listed in PDF and Excel formats:

Persistent Organic Pollutants (POP) regulations apply to most products sold in various countries worldwide. Here are the current EU POP substances listed in PDF and Excel formats:

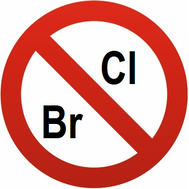

There are several requirements regarding the halogenated compounds used in products, including Persistent Organic Pollutants (POP), Halogen-Free, Low Halogen, RoHS, REACH, and California Proposition 65.

Contrary to POP, halogen-free and low-halogen requirements, including IEC 61249-2-21 and JS709C, are not mandatory; they are just electronics industry recommendations.

IEC 61249-2-21 only applies to printed circuit boards (PCB) and their laminates, whereas JS709C applies to all other components used in electronic products.

Notably, “halogen-free” should logically refer to “no halogen at all”. Nevertheless, standard IEC 61249-2-21 utilizes this term to describe low halogen concentrations.

As with RoHS, Enviropass recommends the documentary approach with suppliers and subcontractors for testing against legal obligations like the European regulation 2019/1021 on persistent organic pollutants and non-mandatory requirements like IEC 61249-2-21 and JS709C on halogen-free and low-halogen.

This method offers the best value for your money, avoiding dozens of expensive analytical tests for potentially dangerous substances in a tested product.

By using the classic approach, you allow Enviropass to tackle the documentary assessment of your products, including:

Note that you can apply for testing services at a lower cost.

In addition to the Classic POP services, Deluxe POP gives you the tools to take control over POP compliance.

Deluxe POP includes:

POP is an acronym for Persistent Organic Pollutants.

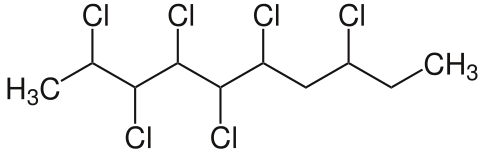

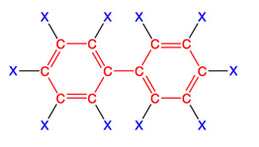

Typically, POP chemicals are halogenated organic compounds that massively originate from industrial activities and manufactured goods, such as electrical and electronic equipment and other types of products.

POPs tend to migrate and accumulate in the cold parts of the world, like the poles.

POP substances exhibit high lipid solubility, because of their brominated or chlorinated molecular structures.

Thus, POPs migrate into the body’s lipids and the environment hardly destroys them. In other words, they bioaccumulate.

The main concern with the POP chemicals is that they may cause health and environmental issues by:

Since the Stockholm Convention of 2004, many jurisdictions and markets around the world have regulated several POP substances.

As a result, various countries prohibit or restrict certain POP substances, such as:

Examples of heavily restricted POP substances include:

Article 3 of the European Regulation 2019/1021 prohibits the use of any POP substances listed in Annex I on their own, in mixtures, or in articles. However, according to Article 4 of that same POP regulation, some exemptions may apply under certain conditions.

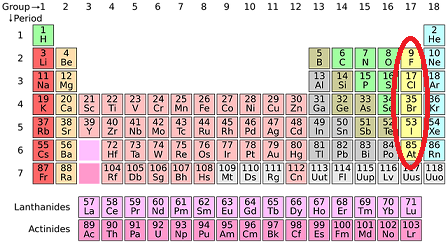

Many engineering applications employ halogenated polymeric materials and compounds. The halogen group contains bromine, chlorine, fluorine, iodine, and astatine. Manufacturers add brominated flame retardants (BFRs) or chlorinated flame retardants (CFRs) to plastic materials, including thermoplastics, solder masks, insulation materials, printed board laminates, etc., to obtain necessary flame retardancy. Additionally, cable jacketing and vibration-damping materials frequently employ polyvinyl chloride (PVC) as their basic resin.

To lessen the negative environmental impacts of halogenated materials and compounds, the electronic industry has been attempting to create dependable and affordable substitutes for these materials and to follow available halogen-free and low-halogen standards.

There are different standards regulating halogenated compounds, including:

The International Electrochemical Commission (IEC) has established the standard IEC 61249-2-21 in response to the concerns about the adverse health and environmental impacts caused by halogens. This standard only applies to PCBs and printed board laminates and defines halogen-free as the following:

Halogens | Threshold |

|---|---|

Chlorine | Less or equals to 900 ppm |

Bromine | Less or equals to 900 ppm |

Total Halogens | Less or equals to 1,500 ppm |

On the other hand, JEDEC has developed standard JS709C. This standard offers definitions for low-halogen electronic devices that may include the halogens bromine and chlorin used as BFRs, CFRs, and PVC. According to this requirement, each component of an electronic product must contain less than 1000 ppm of bromine if it comes from BFRs and less than 1000 ppm of chlorine if it comes from CFRs, PVC, PVC block polymers, PVC congeners, PVC copolymers, or polymer alloys containing PVC. This requirement applies to all materials in electronic products, excluding printed board laminates. Electronic devices may contain plastics with higher bromine and chlorine concentrations as long as these halogens are not used as flame retardants or PVC.

These two standards utilize distinct terminology: JS709C employs the word low-halogen, whereas IEC 61249-2-21 uses the term halogen-free. Additionally, as mentioned above, the concentration limits are slightly different.

Notably, neither of these two standards covers other halogens (i.e., fluorine, iodine, and astatine). Despite being far less frequent than bromine and chlorine, fluorine-based chemicals are becoming more prevalent in electronic components, including flame retardants for polycarbonates. Iodine has extremely few applications and astatine is ineffective since it is a rare radioactive element. Therefore, neither standard ensures that a product is actually “halogen-free” or “low-halogen”. As a result, some companies do further investigations and include fluorine in their assessments.

There are a few more industry standards defining halogen contents used in products, specifically in PBCs, including:

Standard IPC-4101E – Specification for Base Materials for Rigid and Multilayer Printed Boards

Standard UL 746E – Polymeric Materials — Industrial Laminates, Filament Wound Tubing, Vulcanized Fibre, and Materials Used in Printed Wiring Boards

Selling products containing POP chemicals above the national permitted limits is prohibited and can jeopardize the image of your company.

For example, the European Commission maintains the Safety Gate Rapex website exposing products and companies failing to comply with POP, but also RoHS, REACH SVHC, and other regulations.

Non-compliant products are usually withdrawn from the EU market, and product recalls are common.

Do you need to know more about POP and how you can verify compliance? Contact Enviropass!